The choice between an analog and digital ultrasonic plastic welding machine is one of the most important decisions any manufacturer will make.

Both technologies are designed to create fast, durable bonds in thermoplastics — but the way they handle control, precision, and data reporting is fundamentally different.

At Altrasonix, we understand that every production environment has unique demands.

In this guide, we’ll break down the technical and practical differences between analog and digital ultrasonic welders so you can determine which solution best fits your factory’s goals.

Digital Ultrasonic Plastic Welding Machine: Precision, Intelligence & Industry 4.0 Integration

A digital ultrasonic plastic welding machine represents the latest evolution in ultrasonic technology.

Built on a microprocessor-based architecture with intelligent software, these systems deliver unmatched precision, data tracking, and process control — ideal for modern, automated manufacturing lines.

Key Advantages of Digital Ultrasonic Welding Machines

1. Surgical Precision

Digital control systems allow exact parameter settings for time, energy, distance, and pressure — often accurate to 0.01 seconds.

This level of precision is critical for complex assemblies such as medical devices or microelectronic components.

2. Automatic Frequency Tracking

Digital models feature real-time frequency monitoring and automatic adjustment of the generator’s output.

This ensures constant energy transfer and consistent weld quality, even when horn temperature fluctuates during production.

3. Industry 4.0 Ready

With built-in IoT data connectivity (RS232/485), digital ultrasonic plastic welding machines can log, store, and transmit welding data for traceability and quality assurance.

This integration supports smart factory systems and automated production lines.

4. Recipe Management

Operators can store and recall multiple welding programs (recipes) for different products, reducing setup time and minimizing human error during changeovers.

5. Broad Capability Range

Digital platforms typically support multiple frequencies (15 kHz, 20 kHz, 35 kHz) and various power levels, providing flexibility for future manufacturing requirements.

👉 Best For:

- Multi-product production lines

- Quality-sensitive industries (medical, electronics, automotive)

- Manufacturers requiring detailed process monitoring and data traceability

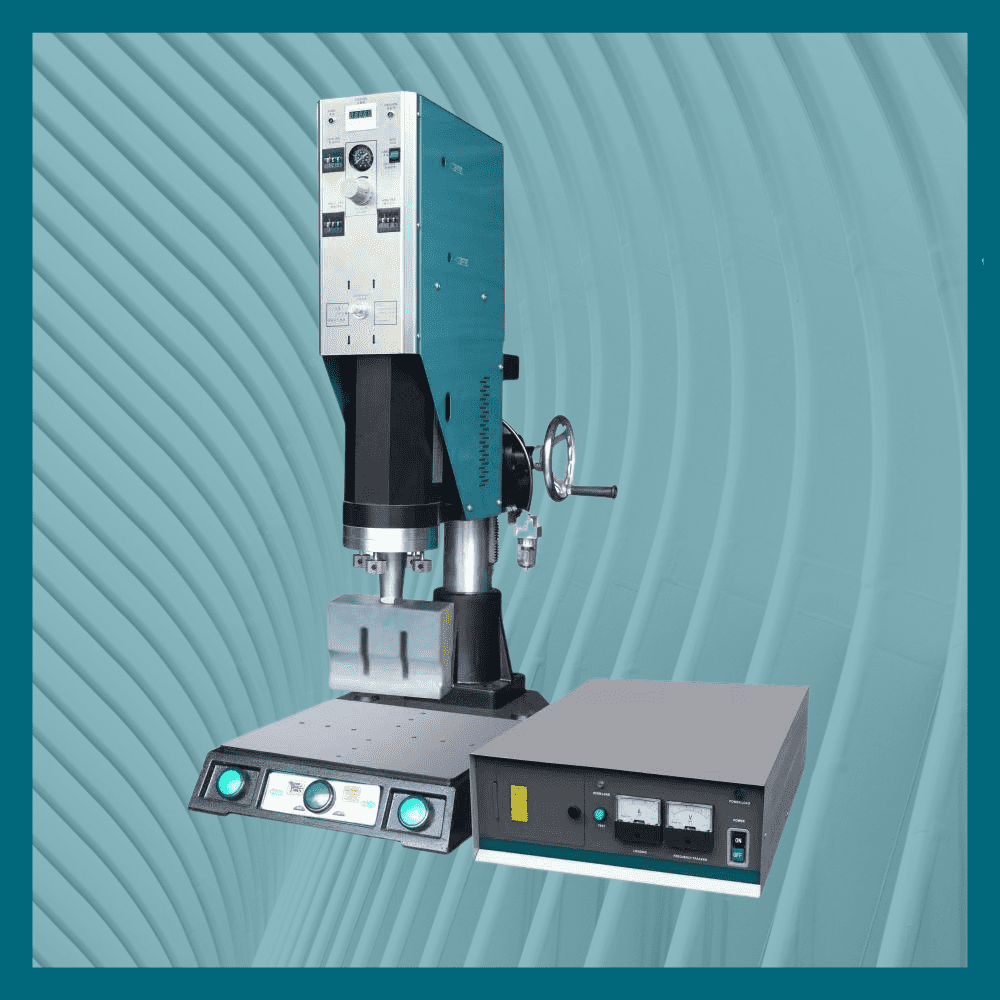

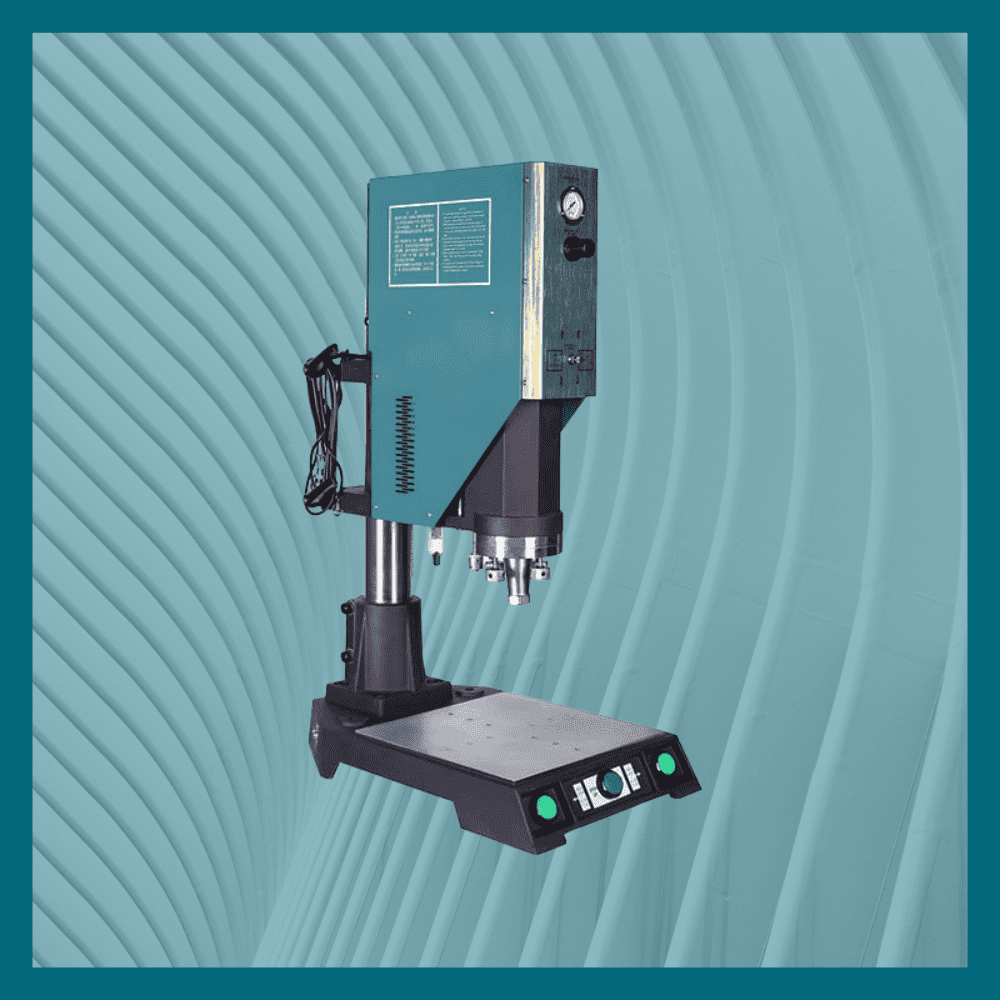

Analog Ultrasonic Plastic Welding Machine: Simplicity, Stability & Long-Term Value

An analog ultrasonic plastic welding machine is the trusted workhorse of the industry — simple, robust, and proven.

Instead of digital microprocessors, analog systems use reliable electronic circuits and transformers, making them highly stable and easy to operate.

Key Advantages of Analog Ultrasonic Welding Machines

1. Proven Stability

Once parameters are manually set, analog systems deliver consistent ultrasonic energy output with minimal variation, ideal for repetitive production.

2. Cost-Effective Investment

The straightforward design of analog machines makes them more affordable, with lower initial investment and minimal maintenance needs.

3. User-Friendly Operation

Analog welders feature simple dials, meters, and switches for intuitive control — perfect for operators with limited training.

4. Industrial Durability

Analog circuitry is less sensitive to electrical noise and can withstand harsh factory environments better than delicate digital boards.

5. Long-Term Reliability

For stable, single-product production, analog machines can deliver decades of consistent service with little maintenance.

👉 Best For:

- Dedicated, high-volume manufacturing of a single part

- Cost-sensitive operations

- Environments requiring rugged, low-maintenance equipment

Making the Right Choice with altrAsonix

Choosing between an analog or digital ultrasonic plastic welding machine depends on your operational priorities — precision, data, or simplicity.

Below is a quick comparison to guide your decision:

| Criteria | Choose Digital | Choose Analog |

|---|---|---|

| Budget | Higher initial investment | Lower purchase cost |

| Quality Control | Detailed data logging, diagnostics, traceability | Basic time/pressure checks |

| Production Variety | Frequent part changeovers, multiple recipes | Consistent, single-part production |

| Required Precision | Micro-level control (medical, microelectronics) | Standard bonding (toys, containers) |

| Automation Readiness | Smart factory & IoT integration | Manual or semi-automatic setup |

At altrAsonix, we manufacture both analog and digital ultrasonic systems — from durable 15 kHz / 3200 W analog welders to advanced digital ultrasonic machines with IoT connectivity and full process control.

Whether your goal is simplicity and stability or data-driven precision, altrAsonix delivers the perfect ultrasonic plastic welding solution for your production floor.