In today’s fast-paced manufacturing world, efficiency, precision, and sustainability are more than just goals—they’re essential. At altrAsonix, we’re proud to be at the forefront of innovation with our Ultrasonic Plastic Welding Machines, designed to deliver flawless performance and uncompromising quality in every weld.

What is Ultrasonic Plastic Welding?

Ultrasonic plastic welding is an advanced joining process that uses high-frequency ultrasonic vibrations—typically between 15 kHz and 40 kHz—to bond thermoplastic materials. Instead of using glues, solvents, or mechanical fasteners, this method creates a strong, clean, and permanent weld by generating frictional heat at the joint interface. The result? A seamless bond formed within fractions of a second.

Why Choose Ultrasonic Welding?

Unlike traditional methods, ultrasonic welding offers a range of benefits that make it the preferred choice across industries:

- Speed & Efficiency: Each welding cycle takes less than a second, drastically increasing production output.

- Eco-Friendly: Eliminates the need for adhesives and chemicals, reducing waste and environmental impact.

- Strong & Precise Bonds: Ensures repeatable, high-strength welds even for complex part geometries.

- Low Operating Cost: Minimal energy consumption and low maintenance requirements.

- Aesthetic Finish: Produces clean, mark-free joints without discoloration or residue.

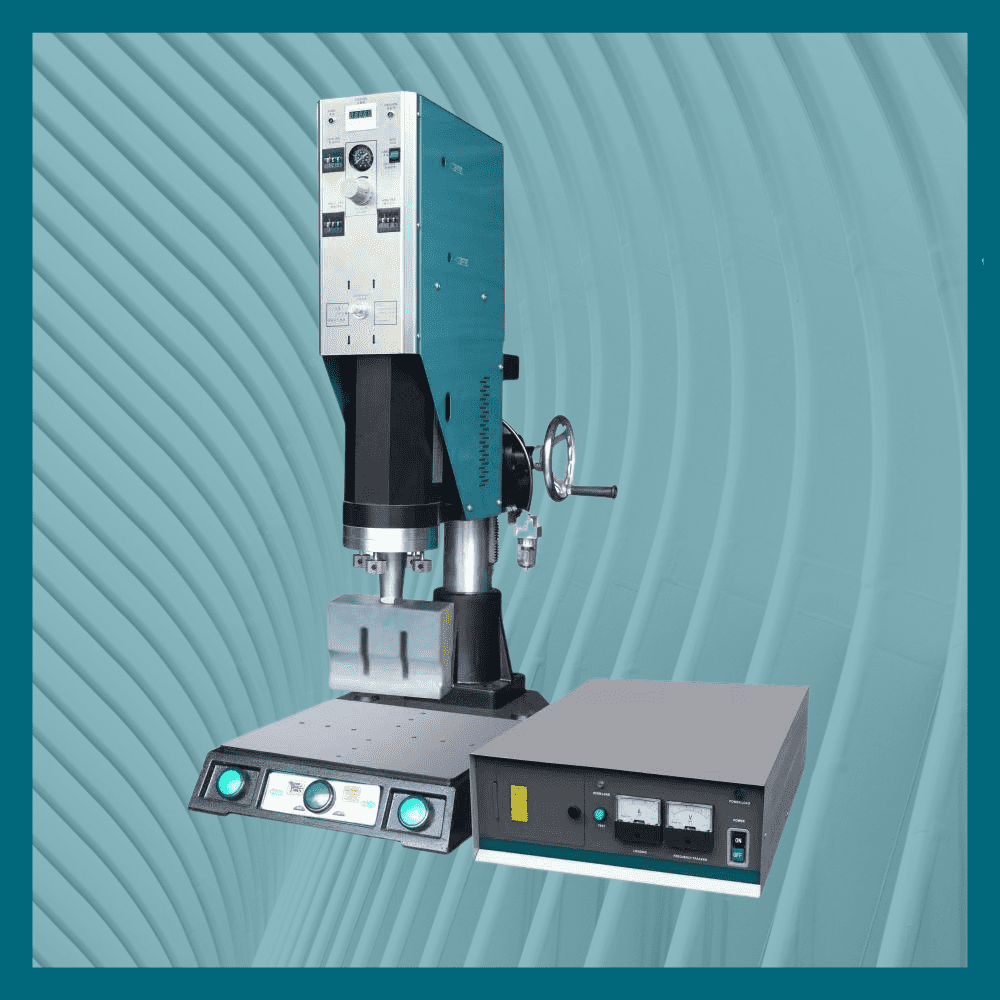

altrAsonix Ultrasonic Plastic Welding Machines

At altrAsonix, we design and manufacture digital ultrasonic welding machines that integrate cutting-edge technology with user-friendly operation. Our systems—available in 15 kHz, 20 kHz, 28 kHz, and 35 kHz models—are engineered to meet the diverse needs of industries such as automotive, electronics, medical, packaging, and consumer goods.

Key Features of altrAsonix Machines:

- Digital Frequency Control: Ensures stable performance and automatic tuning for consistent weld quality.

- Multiple Welding Modes: Time, energy, power, and depth control for precise and flexible operation.

- Touch-Screen Interface: Easy to set up, monitor, and adjust parameters with real-time data feedback.

- Heavy-Duty Construction: Built for durability and long-term reliability in industrial environments.

- Custom Solutions: Tailored designs available for specialized applications and materials.

Applications Across Industries

Ultrasonic plastic welding is used in a wide variety of applications, including:

- Automotive: Instrument panels, bumpers, lighting housings, and sensors.

- Electronics: Battery packs, switches, and circuit housings.

- Medical: Filters, masks, valves, and diagnostic devices.

- Consumer Goods: Toys, tools, appliances, and packaging.

Wherever precision and performance matter, altrAsonix technology delivers.

Why Partner with AltrAsonix?

With years of experience and innovation, altrAsonix stands as a trusted leader in ultrasonic solutions. From design consultation to after-sales support, our team ensures that every customer achieves the perfect balance of efficiency, reliability, and cost-effectiveness in their production line.

Experience the Future of Welding

At altrAsonix, we believe the future of manufacturing is smart, sustainable, and seamless—and ultrasonic plastic welding is leading that transformation. Whether you need a standard machine or a customized system for unique applications, we’re here to help you weld better, faster, and greener.