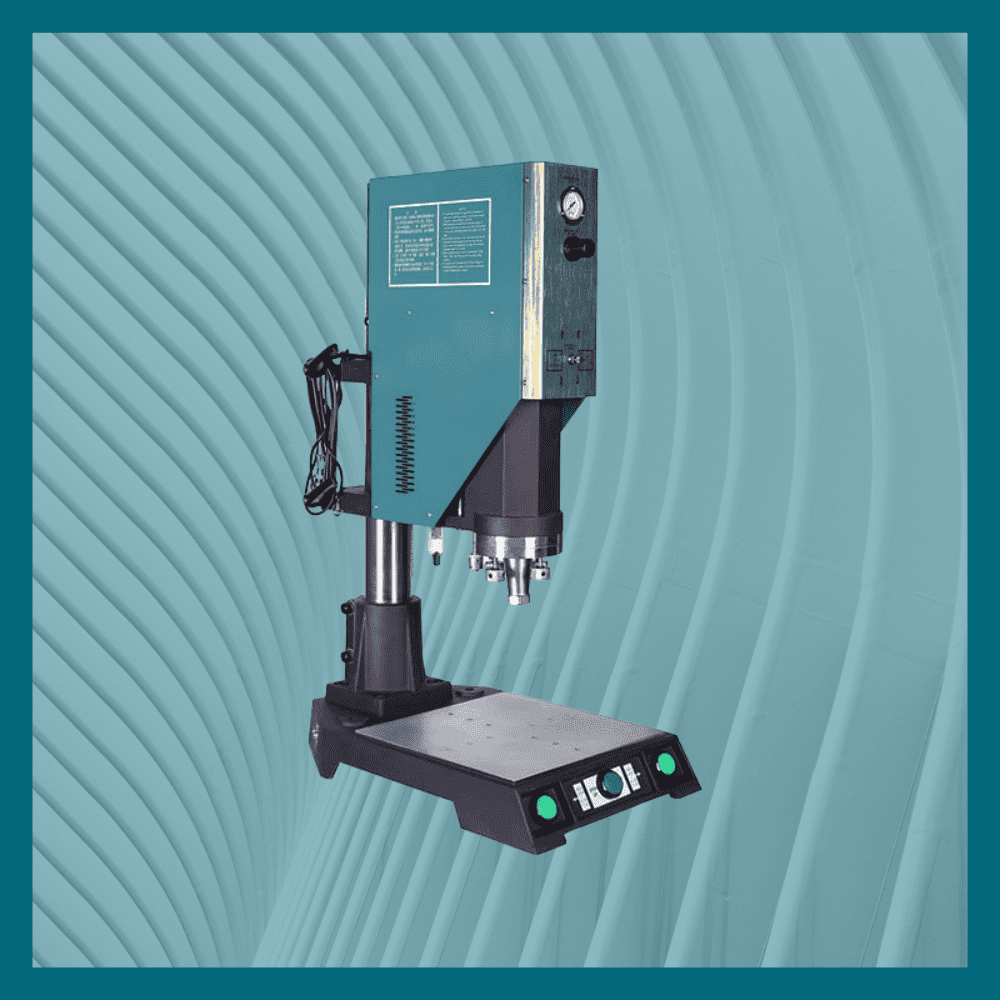

Operating an ultrasonic plastic welding machine requires precision, regular maintenance, and proper setup. Whether you are using a digital or analog ultrasonic welder, following the correct operating procedures ensures consistent weld quality and long machine life.

However, even the most reliable machines may occasionally face minor issues. Before calling for technical service, it’s important to perform a few basic checks that can often resolve the problem quickly.

At altrAsonix, we’re committed to helping you keep your equipment running smoothly. Here’s a practical guide on what to check if your ultrasonic machine is not working as expected.

Key Things to Keep in Mind During Operation

- Ensure Proper Power Supply

- Always connect your ultrasonic welder to a stable AC 220V power source.

- Avoid power fluctuations — use a voltage stabilizer or UPS in areas with inconsistent electricity.

- Check Air Pressure and Connections

- Verify that the air pressure (0–7 bar) is set correctly.

- Make sure air hoses are securely connected and free from leaks or blockages.

- Inspect the Transducer and Horn (Sonotrode)

- Ensure the ultrasonic horn and booster are clean, properly tightened, and free from cracks.

- Dust, oil, or residue on the horn surface can reduce welding efficiency.

- Verify Frequency Match

- Confirm that the machine’s generator frequency (15 kHz, 20 kHz, etc.) matches the installed transducer and horn.

- A mismatch can cause weak welds or machine shutdowns.

- Monitor Overload or Alarm Indicators

- If your ultrasonic plastic welding machine shows an overload error, stop the machine immediately.

- Common causes include incorrect amplitude settings, horn wear, or improper part alignment.

- Keep the Work Area Clean

- Remove debris, leftover parts, or liquids near the machine.

- Cleanliness prevents vibration damping and ensures precise horn alignment.

- Perform Routine Maintenance

- Tighten screws, clean filters, and inspect electrical connections regularly.

- Routine care reduces downtime and extends the life of your ultrasonic system.

Machine Not Working? Try These Basic Troubleshooting Steps

If your ultrasonic welding machine isn’t operating correctly, follow this quick checklist before requesting service:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Machine won’t power on | Power supply issue | Check voltage, cable, and fuse |

| Weak or inconsistent welds | Horn/transducer contamination | Clean and reassemble properly |

| Machine overload alarm | Frequency mismatch or mechanical issue | Recheck horn frequency and part alignment |

| No ultrasonic output | Generator failure or wiring issue | Inspect cables and connections |

| Irregular vibration sound | Loose horn or booster | Tighten components and test |

Contact altrAsonix Technical Support

If you’ve tried the above troubleshooting steps and your ultrasonic plastic welding machine still isn’t functioning properly, don’t worry — expert help is just a call away.

📞 Contact Us: +91 9599711448 / +91 9599711449

Our trained technicians will guide you through advanced diagnostic checks or schedule an onsite service visit if required.

At altrAsonix, we believe in long-term customer support — ensuring your ultrasonic equipment performs at its peak every single day.