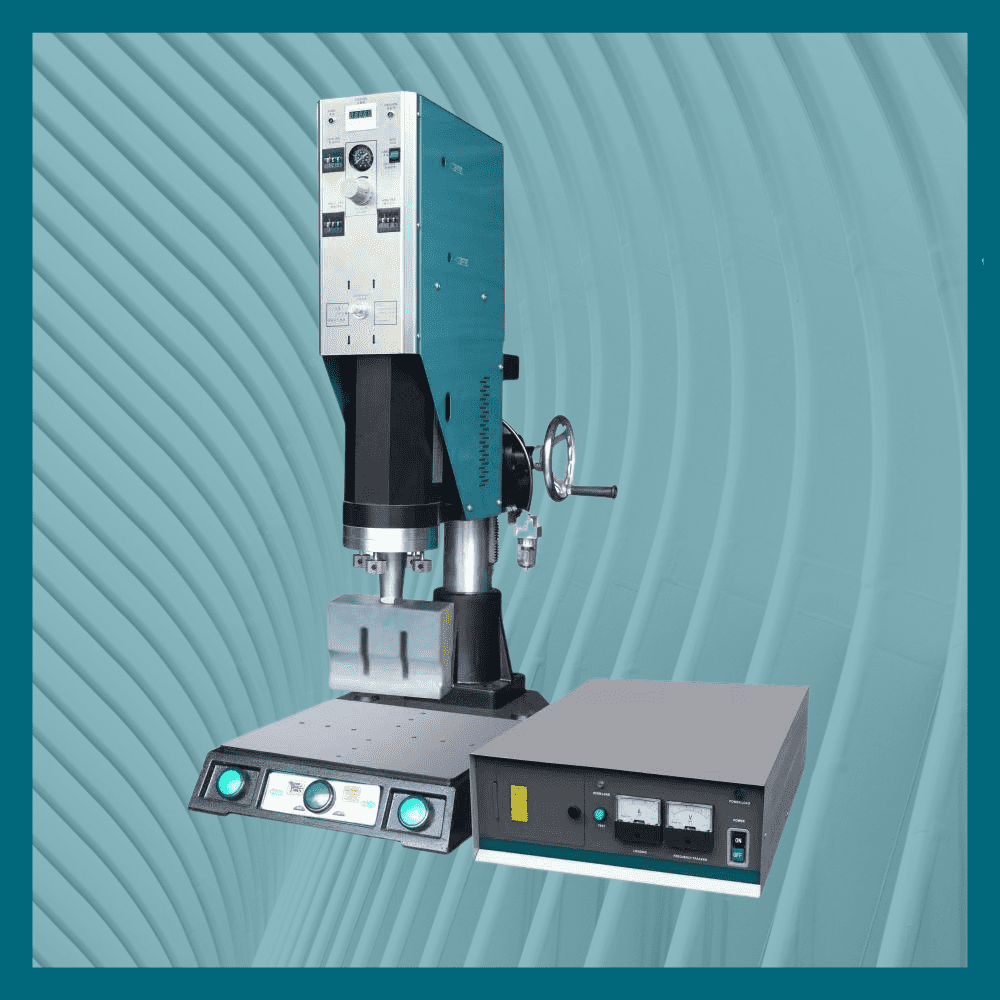

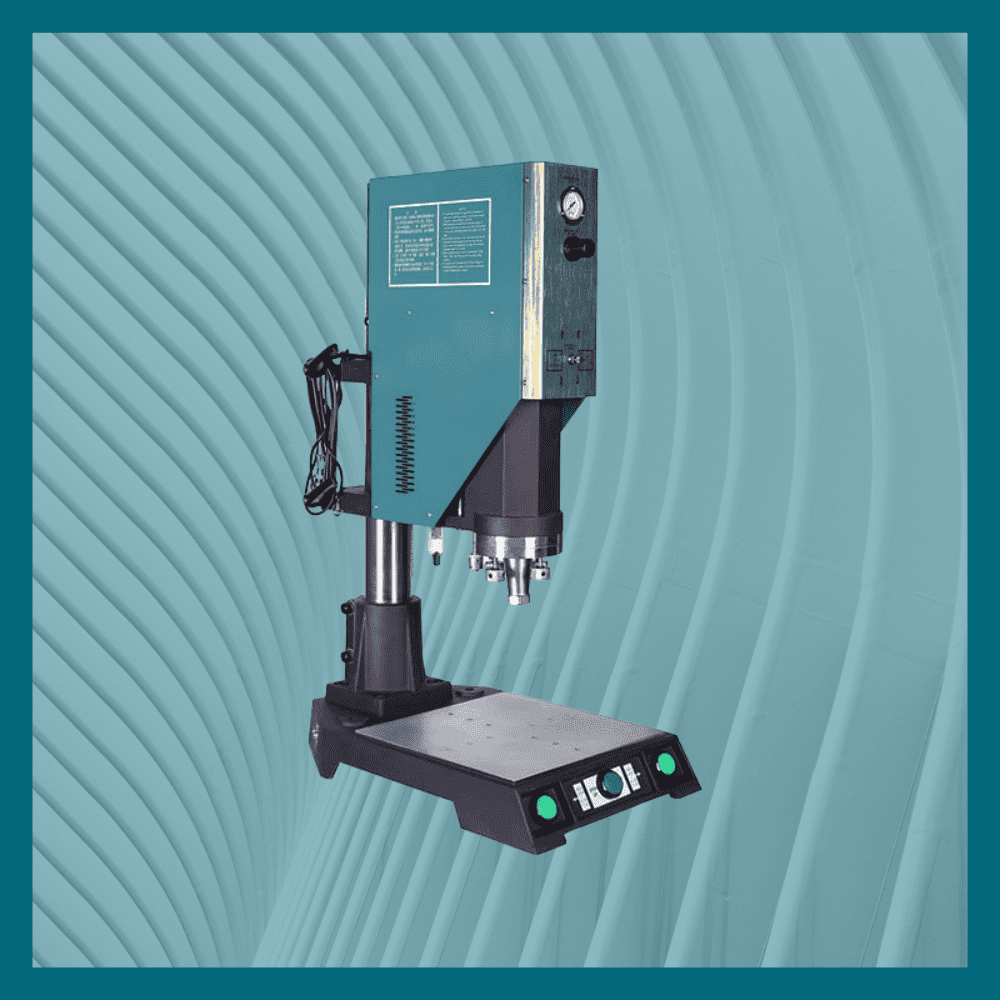

20 kHz ultrasonic plastic welding machine has become a widely adopted solution for industrial plastic joining due to its reliability, deeper weld penetration, and suitability for medium to large components. As manufacturers push for cleaner, faster, and more efficient production in 2025, this technology has rapidly gained prominence.

What Makes the 20 kHz Ultrasonic Plastic Welding Machine Different?

A 20 kHz system operates at a lower frequency and delivers higher amplitude vibration compared to high-frequency welders. This combination allows industrial users to weld thick, rigid, or engineering-grade thermoplastic components with stronger and cleaner joints.

Why Industries Are Choosing the 20 kHz Ultrasonic Plastic Welding Machine

1. High-Amplitude Welding Capability

One of the leading advantages of the 20 kHz ultrasonic plastic welding machine is its ability to generate powerful amplitude. This helps in achieving strong molecular bonding for thicker plastic sections that require deep energy transfer.

2. Suitable for Large and Complex Plastic Components

The 20 kHz frequency supports larger horn sizes and broader energy distribution, making it ideal for dashboards, automotive covers, appliance panels, and industrial housings.

3. Compatibility with Engineering-Grade Plastics

Materials such as ABS, PC, PP, PBT, Nylon, and their composites respond very well to the welding characteristics of a 20 kHz unit.

4. Improved Production Speed

The welding cycle is extremely fast—often a fraction of a second—allowing manufacturers to increase throughput while maintaining high consistency.

5. Lower Cost of Operation

Since ultrasonic welding does not require solvents, adhesives, screws, or consumables, long-term operational costs are significantly reduced.

Industries Using the 20 kHz Ultrasonic Plastic Welding Machine

20 KHz Ultrasonic Plastic Welding Machine

| Technical Specification (Typical) | Details |

|---|---|

| Working Frequency | 20 kHz |

| Output Power | 2000 W |

| Welding Modes | Time / Energy |

| Control System | Digital touch-screen HMI |

| Power Supply | AC 220V |

| Air Pressure Requirement | 0.2–0.6 MPa |

| Welding Stroke | Adjustable (typically 50–100 mm) |

| Material Compatibility | ABS, PP, PE, PC, PVC, PS, PMMA, Nylon, and other thermoplastics |

Automotive Manufacturing

Used in instrument clusters, air filter housings, sensors, and interior components.

Electronics and Appliances

Ideal for joining casings, control module parts, and structural plastic elements.

Medical Device Assembly

Supports precise bonding for diagnostic housings and sterile medical-grade plastics.

Industrial Plastics and Assemblies

Used for robust joining in electrical boxes, power tools, and heavy-duty enclosures.

Key Features to Look for in a 20 kHz Ultrasonic Plastic Welding Machine

Digital Frequency Control

A modern system automatically tracks and maintains resonance for stable performance.

Multiple Welding Modes

Modes like Time, Energy, or Peak Power give operators flexibility for different part designs.

Programmable Amplitude Settings

Adjustable amplitude ensures delicate components can be welded without over-melting.

Rigid Mechanical Structure

A strong frame prevents vibration loss, ensuring consistent accuracy under continuous use.

High-Quality Tooling Support

The horn and fixture design determine weld accuracy, repeatability, and long-term machine performance.

Why Choose altrAsonix for Your 20 kHz Ultrasonic Plastic Welding Machine?

altrAsonix offers engineering-grade ultrasonic welding systems built for modern production environments. The machines deliver:

- Stable, high-power output

- Long-duty cycle reliability

- Precision digital or analog generator options

- Customized horns and fixtures

- Expert technical support

These factors make altrAsonix a dependable partner for industries that rely on ultrasonic assembly.

How to Select the Right 20 kHz Ultrasonic Plastic Welding Machine

Evaluate Plastic Material and Weld Design

Identify melting temperature, part geometry, and the expected weld strength.

Match Power Rating to Application

Machines typically range from 2000W to 4200W. Higher power improves weld consistency for large assemblies.

Check Availability of Tooling Customization

Horn design plays a crucial role in ensuring proper energy distribution.

Ensure Reliable After-Sales Service

Service support determines long-term machine performance and production stability.

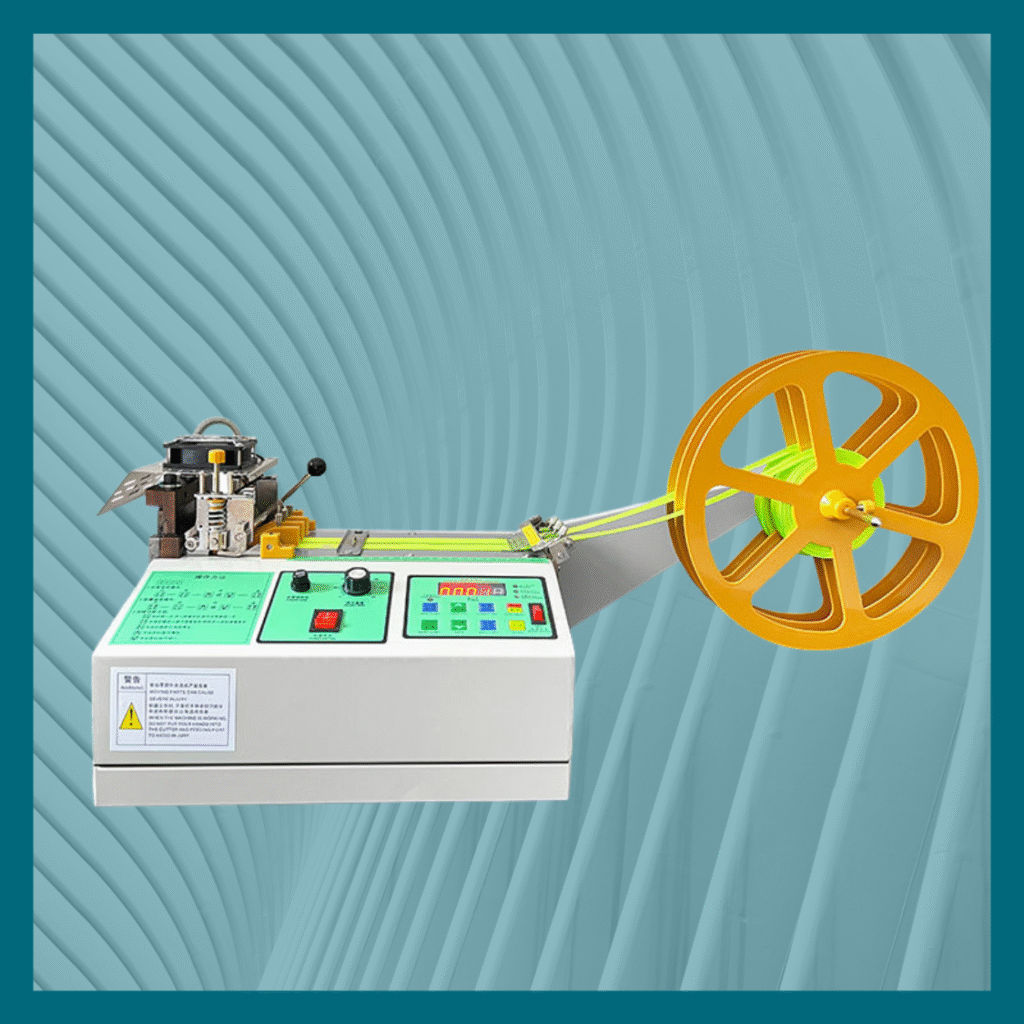

Advantages of Using an Ultrasonic Plastic Welding Machine for High-Volume Production

High-volume manufacturers across automotive, electronics, medical, and consumer goods industries increasingly rely on an ultrasonic plastic welding machine because of its unmatched speed, precision, and repeatability. When production lines must output thousands or even millions of plastic components per month, traditional joining methods such as adhesives, screws, or heat sealing become slow, inconsistent, and expensive. An ultrasonic plastic welding machine solves these challenges with a fast, reliable, and fully automated welding process that significantly improves efficiency.

Conclusion: The Role of the Ultrasonic Plastic Welding Machine

The 20 kHz ultrasonic plastic welding machine has become an essential tool for industries that require strong, efficient, and repeatable plastic joining. Its ability to handle large parts, engineering materials, and continuous high-speed production makes it one of the most valuable machines in modern manufacturing environments.

Manufacturers looking for long-term reliability, cost efficiency, and process stability consistently choose the 20 kHz ultrasonic plastic welding machine for their production lines.