Why Buying an Automated Ultrasonic Plastic Welding Machine Online Is Easier Today

If you want to buy automated ultrasonic plastic welding machine online, you now have more reliable options than ever before. Many manufacturers offer detailed product pages, videos, and technical sheets, which makes the selection process simple and transparent. As a result, even first-time buyers can confidently compare features, evaluate power ratings, and select the right machine that fits their production line.

What Is an Automated Ultrasonic Plastic Welding Machine?

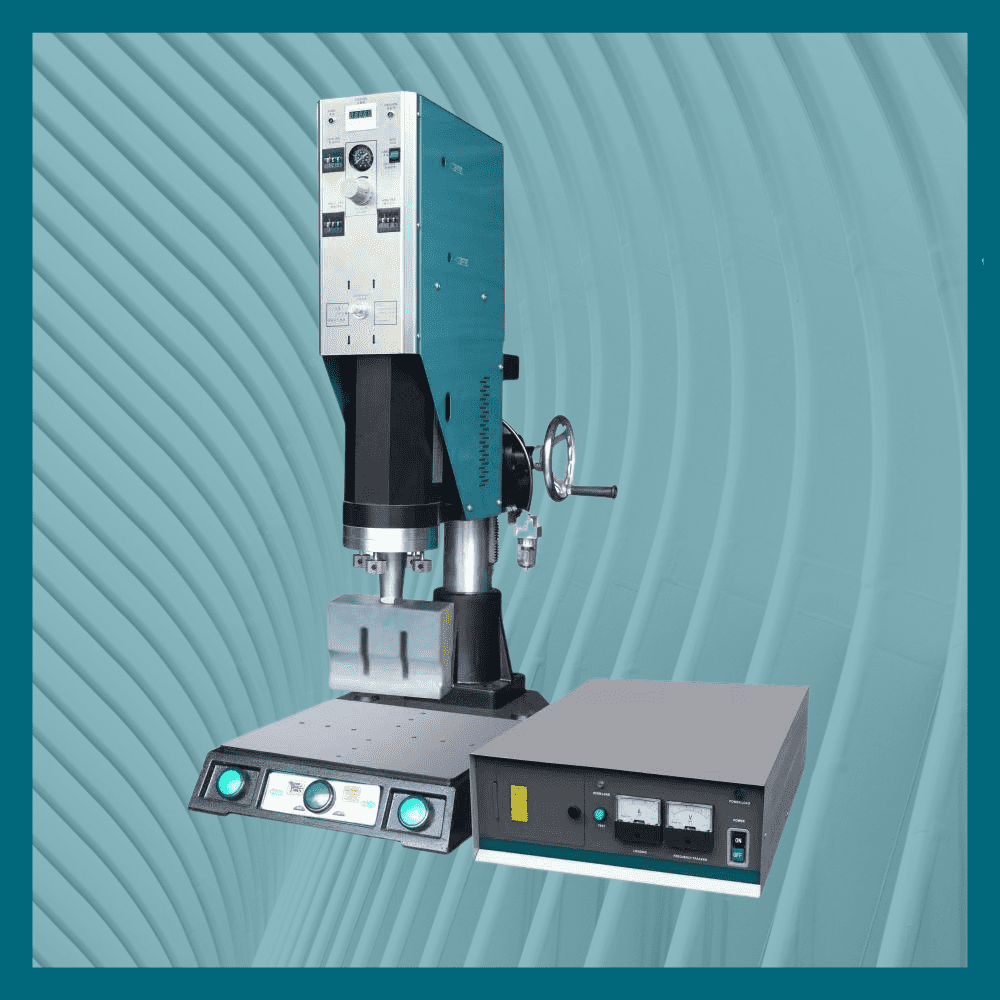

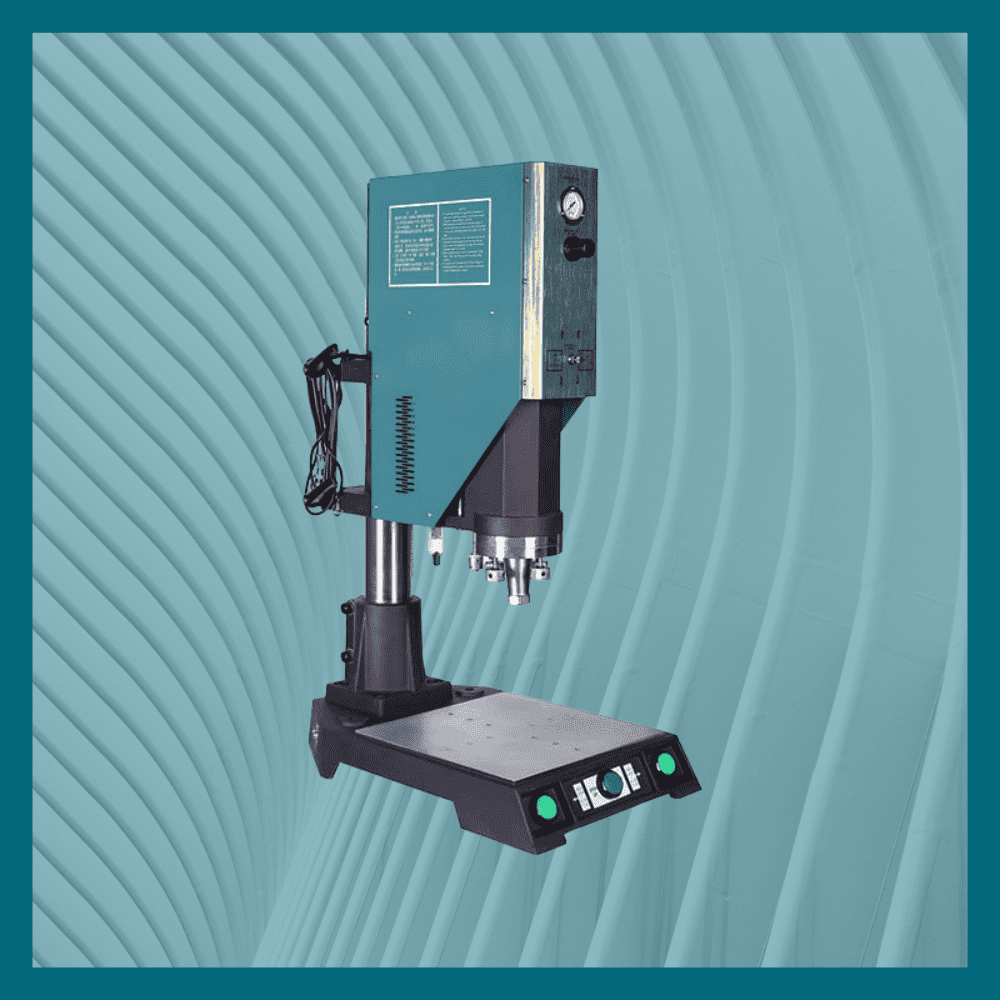

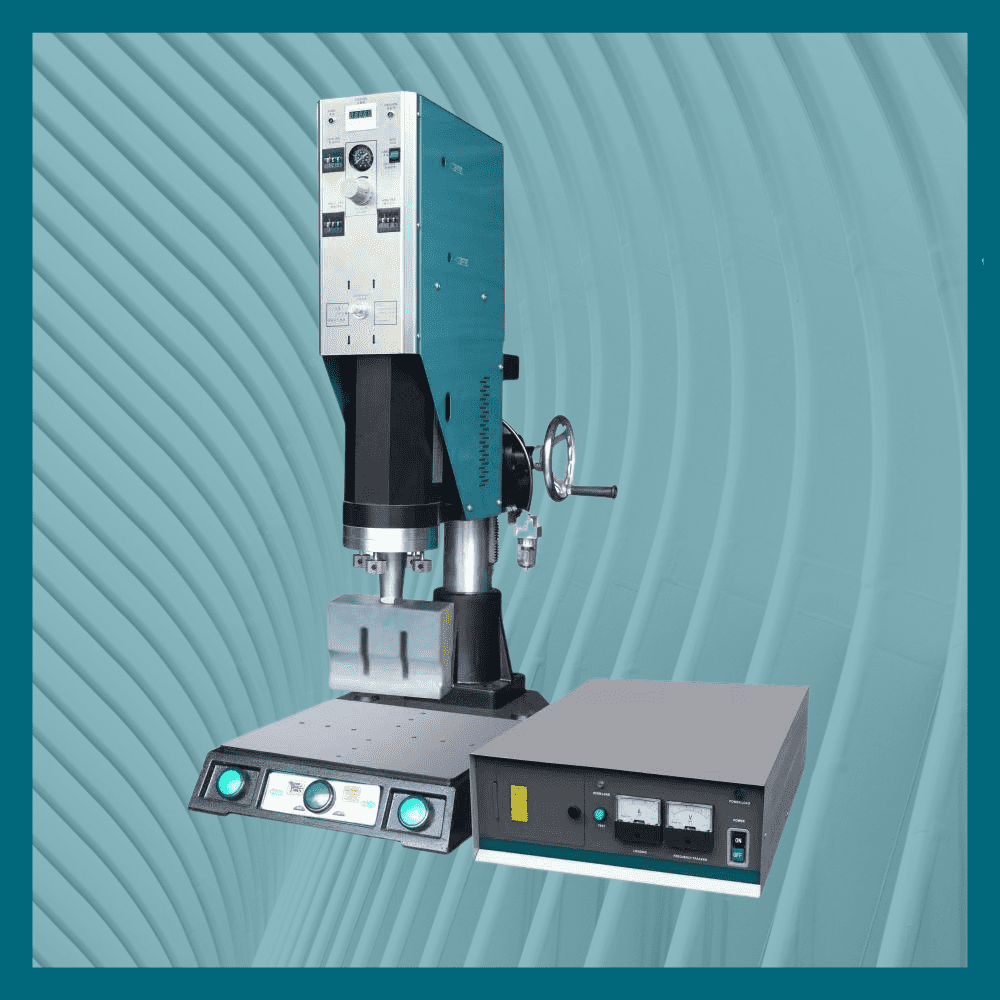

An automated ultrasonic welder is a system that joins plastic parts using high-frequency vibration. Unlike manual models, automated machines control pressure, weld time, amplitude, energy output, and part positioning through a programmed interface. Because of this automation, the machine produces consistent welds with minimal operator involvement.

Why Most Buyers Prefer to Buy Automated Ultrasonic Plastic Welding Machine Online

1. Easy Product Comparison

When you buy automated ultrasonic plastic welding machine online, it becomes simple to compare models from different brands. You can check power levels, welding modes, speed, tooling options, and certifications. Additionally, online platforms display reviews, which helps you understand real user experiences.

2. Access to Updated Technical Information

Online listings usually include the latest specifications, such as generator type, frequency, power output, and automation compatibility. Moreover, many suppliers upload manuals, videos, and diagrams, which helps you understand the machine before you make a purchase.

3. Transparent Pricing and Offers

Buying online allows you to compare pricing across multiple suppliers. As a result, you can identify discounts, warranty offers, and package upgrades. This transparency helps you avoid overpaying.

4. Faster Delivery and Installation Support

Because online suppliers often process orders quickly, you receive the machine sooner. Furthermore, most brands arrange on-site installation and training, which reduces setup time and helps you start production without delay.

Key Factors to Consider Before You Buy Automated Ultrasonic Plastic Welding Machine Online

15 KHz Ultrasonic Plastic Welding Machine

| Technical Specification (Typical) | Details |

|---|---|

| Working Frequency | 15 kHz |

| Output Power | 2600 W |

| Welding Modes | Time / Manual |

| Control System | Manual |

| Power Supply | AC 220V |

| Air Pressure Requirement | 0.2–0.6 MPa |

| Welding Stroke | Adjustable (typically 50–100 mm) |

| Material Compatibility | ABS, PP, PE, PC, PVC, PS, PMMA, Nylon, and other thermoplastics |

1. Power Rating and Frequency

Automated ultrasonic welders typically come in 15 kHz, 20 kHz, 28 kHz, and 35 kHz models. While lower frequencies offer higher power, higher frequencies support fine and delicate welding. Therefore, choose a frequency based on part size and material type.

2. Automation Level

Some machines come with basic automation like programmable weld cycles. Others offer full automation with conveyors, robots, and part feeders. As a result, your choice should match your production volume.

3. Weld Modes and Controls

Always check if the machine includes time, energy, and power modes. These modes help maintain consistency across large batches. In addition, advanced digital controls improve repeatability.

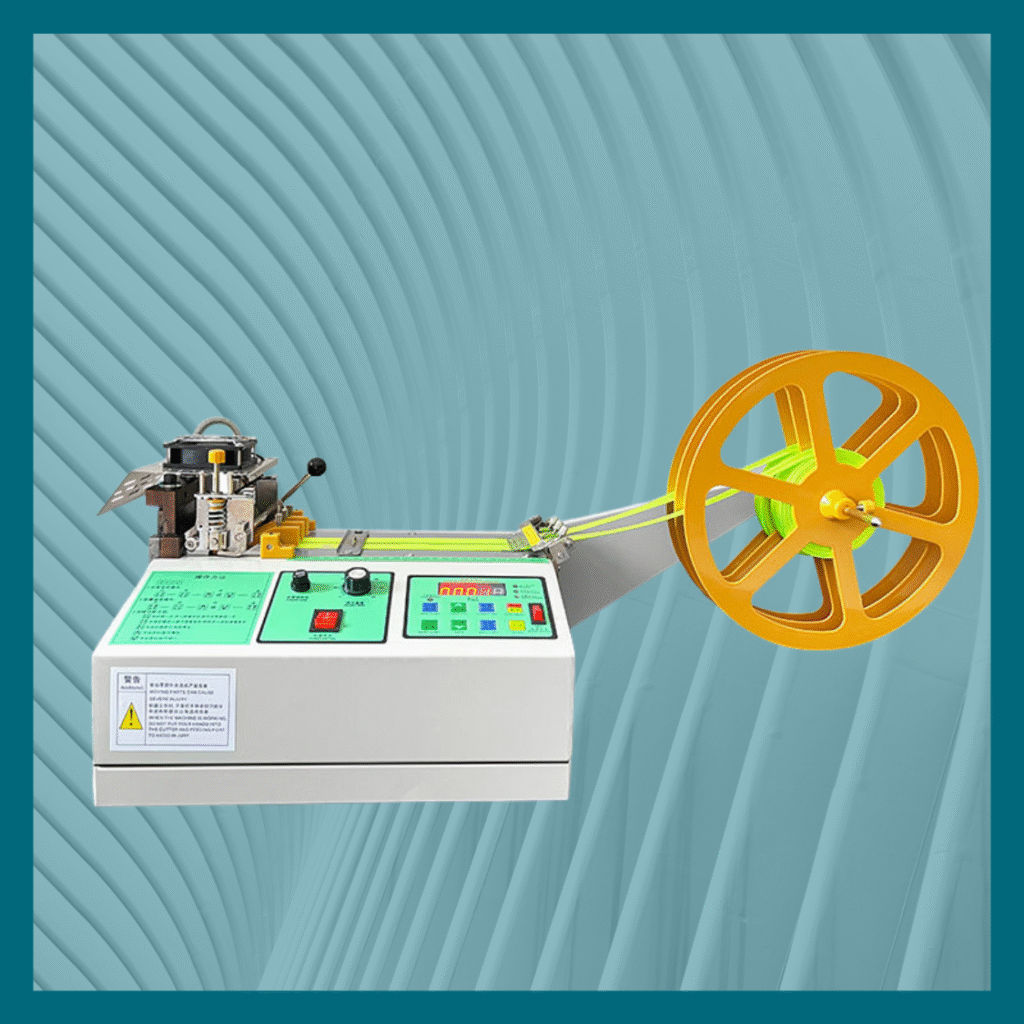

4. Tooling and Fixture Support

Good tooling ensures accurate weld placement. Therefore, make sure the supplier can design custom horns and fixtures if required.

5. After-Sales Service and Warranty

Service quality matters because ultrasonic welders need tuning, calibration, and periodic horn maintenance. Because of this, always select a supplier with reliable support.

Common Mistakes to Avoid When You Buy Automated Ultrasonic Plastic Welding Machine Online

1. Ignoring Material Compatibility

Different plastics respond differently to ultrasonic energy. Therefore, confirm material compatibility before you buy.

2. Choosing a Machine With Low Power

Low-power systems may fail to weld thicker parts. Consequently, always check that the power rating matches your production needs.

3. Not Reviewing Sample Weld Tests

A reputable supplier will offer weld samples. When you test these samples, you ensure the machine performs well before purchasing.

Benefits of Buying From a Trusted Supplier Like altrAsonix

altrAsonix provides high-performance automated ultrasonic welding systems designed for industrial use. In addition, the brand offers custom tooling, installation training, and strong after-sales support. These benefits make your buying process smooth and reliable.

Conclusion: The Smart Way to Buy Automated Ultrasonic Plastic Welding Machine Online

When you buy automated ultrasonic plastic welding machine online, you gain access to detailed product data, clear pricing, fast delivery, and expert support. By comparing specifications, evaluating automation levels, and checking service options, you can choose the right machine with confidence. This guide helps you make a smooth and informed purchase decision that supports long-term production success.