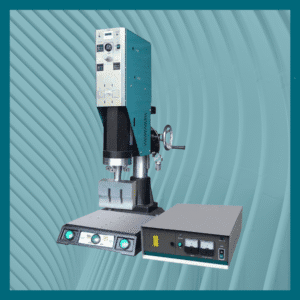

Ultrasonic Plastic Welding Machine for Smoke Detector Housing from altrAsonix is specially developed for manufacturing high-reliability smoke detector casings used in residential, commercial and industrial fire safety systems. These housings require airtight joints to ensure proper air-flow management and accurate smoke detection.

Why Digital Ultrasonic Welding is Necessary for Smoke Detector Production

Smoke detector housings must maintain zero air leakage, precise alignment, and consistent structural integrity to prevent false alarms or sensor malfunction. The 20 kHz digital machine provides controlled amplitude, constant frequency tracking and precise energy delivery, making it ideal for such safety-critical assemblies.

Suitable for Both Ionization and Photoelectric Detector Designs

Modern smoke detectors consist of multiple enclosure sections, vents, sensor chambers and safety locks—requiring consistent and clean welding without damaging the internal sensors or PCB. The digital ultrasonic welder provides this accuracy while maintaining complete reliability in mass production.

Key Features

Airtight and Leak-Proof Sealing

Ensures proper airflow control for smoke detection accuracy.

Digital Frequency Tracking for Critical Electronics

Maintains constant weld energy even under load variations.

Safe for Sensor Modules and PCBs

Minimizes vibration transfer, protecting optical and ionization chambers.

Uniform Weld Strength with High Repeatability

Ideal for high-volume production and quality-sensitive fire safety components.

Supports Complex Multi-Part Detector Designs

Perfect for housings with vents, grills, locking tabs and back covers.

Energy, Time and Manual Mode Selection

Allows advanced control over weld quality and material melt depth.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | UPM-20K-2000W-DIGITAL |

| Frequency | 20 kHz |

| Power Output | 2000W |

| Welding Mode | Time / Manual / Energy |

| Rectifier Type | Digital |

| Input Voltage | AC 220V |

| Operation Type | Manual |

| Weight | Approx. 90 kg |

| Used For | Smoke detector housings, fire alarm casings, ABS/PC safety enclosures, leakage-sensitive electronic shells |

Best Materials for Smoke Detector Housing Welding:

-

ABS

-

PC

-

PC/ABS blends

These materials create stable, airtight welds for safety-critical devices.

Product Applications in Detail

Smoke Detector Casing Assembly

Provides leak-proof and structurally sound joints for optical and ionization detectors.

Fire Alarm Plastic Housing

Ensures reliable sealing for home, office and industrial alarm devices.

Photoelectric Detector Body Welding

Perfect for housings requiring controlled air vents for sensor accuracy.

IoT and Smart Smoke Sensor Enclosures

Suitable for Wi-Fi enabled and smart home fire detection devices.

Multi-Part Safety Shell Assembly

Supports welding of top covers, bottom covers, vent grills and locking mechanisms.

Battery Compartment Integration

Allows secure welding without affecting battery chamber functionality.

Reviews

There are no reviews yet.